Versatility, Innovation, And Simplicity – We Know The Drill

We know the drill - producers want a simple, yet innovative and versatile grain drill to take their precision and performance to the next level. Great Plains newest drill, the BD7600, brings these key features to today's producers.

We Know The Drill - Producers Want A Drill With Versatility And Flexibility To Open The Door For New Planting Possibilities.

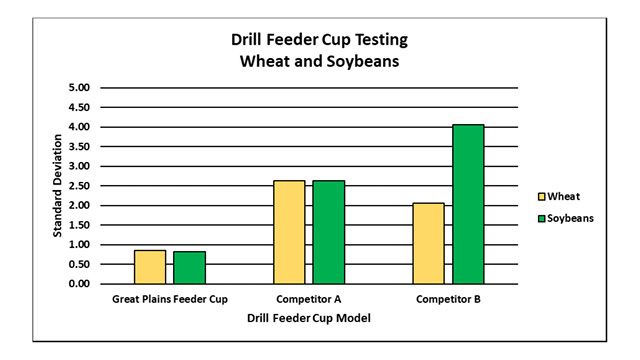

The versatility of the BD7600's new feeder cup is what sets this drill apart from others in the industry. Unmatched by the competition, the feeder cup has proven to be highly accurate across a wide range of seed types from garbanzo beans to clover. Figure 1 shows the standard deviation between the new Great Plains feeder cup and competitors. Standard deviation refers to the level of variance and the feeder cup's ability to deliver seed at a consistent threshold. As the chart shows, Great Plains' new feeder cup design offers a high degree of accuracy and little variance when seeding.

The core component of the feeder cup is the standard seed wheel and small seeds wheel. A large seed and fertilizer wheel can be installed in the place of the standard seed wheel. As the seeds are metered, the chevron seed gate design distributes seed more evenly as it flows into the seed tube - improving spacing accuracy between seeds. This is one of the unique features of the new feeder cups.

Once the seed has been accurately and consistently metered from the feeder cup, the next step to achieving a uniform stand is ensuring the seed reaches the seed trench as smoothly as possible. Traditional grain drill seed hoses are corrugated to flex with the openers as they are raised and lowered. Large and medium-sized seeds typically flow through these corrugations without any issues. However, small seeds often become caught in the corrugated ridges, causing issues with seed spacing and consistent seed rates across the field. To combat these issues, the BD7600 is offered with Needham seed tubes. Needham seed tubes are another innovative feature to maximize drill efficiency. The seed tubes are smooth on the inside to allow seed and fertilizer to low freely. These seed tubes help to ensure that producers' inputs are placed properly - avoiding costly hang-ups and inconsistent seeding.

The feeder cup's functionality combined with the split-box option and row shut-off also provides flexibility to producers who plant multiple crops simultaneously - eliminating the cost and time spent making multiple passes. The split box on previous Great Plains drills was designed to apply dry fertilizer with the seed at planting. In the past, if a producer had an interest in planting small seeds, a separate small seeds attachment had to be installed. While applying fertilizer with the split box is still one of its primary functions, it should be noted that the feeder cup now allows for the split-box option to be used as a secondary seed box. For this reason, there is no longer a need for a stand-alone small seeds box. The split-box option allows producers to seed traditional companion crops, such as alfalfa and oats, and accurately seed different cover crop mixes. Cover crop producers can now rely on the split capabilities to separate the larger seeds from the small seeds in the mixture, avoiding issues with seed settling and non-uniform distribution. Additionally, seed placement is improved when using this practice. The front portion of the split box places seed directly into the trench between the double-disc openers, while the rear portion of the split box drops the seed on top of the seed trench, in front of the press wheel, for shallow placement of small seeds.

For farmers who grow cereal rye as a companion cover crop with soybeans, the split-box design and row shut-off offer additional benefits for this novel practice. This practice typically involves planting the soybeans with a 3011 planter and then drilling the rye in a two-pass system. With the split-box option and seed gates that can be closed off independently, the BD7600 can be configured to plant soybeans on 3011 rows and seed rye on 7 .511 spacings - all in one pass. While these practices may not currently be the norm, the flexibility and versatility of the BD7600 drill and feeder cup may make these unique practices more feasible and profitable for those pursuing new and alternative cropping methods.

We Know The Drill - Producers Want A Drill Complete With Innovations To Maximize Efficiency And Crop Yields.

The BD7600 also features an innovative hydraulic drive. Hydraulic drive offers producers access to automatic section control as well as on-the-go, variable-rate seeding. Using a hydraulic drive allows farmers to save on seed and fertilizer input costs by reducing overlap, as well as improving yields by reducing skips or double-planted areas of the field. The benefits of section control are very apparent on irregular-shaped fields by reducing double planting of the headland borders. A study by the Alabama Cooperative Extension System found that automatic section control combined with tractor guidance technology could increase overall seed savings from 3 to 35 percent per field, depending upon field size and shape

Innovations like hydraulic drive open up the possibility for new technologies like variable-rate seeding. Variable-rate seeding is a recent technology most often utilized on row-crop planters or air drills. However, the hydraulic drive capabilities on the BD7600 allow the seeding rates to be changed throughout the different management zones of a field. For example, producers who wish to benefit from narrow rows of 7.5" or 10" spacing, now have the opportunity to increase yields and maximize their seed investment, especially when planting expensive seeds like soybeans, canola, and certified wheat. This optional system reduces moving parts for ease of maintenance and operation. It also adds an enhanced, ISOBUS-compatible user interface using the DrillCommand™ display for section and rate control.

We Know The Drill - Producers Want A Simple Drill That Offers Practical Features To Make Life Around The Farm A Little Easier.

One BD7600 feature that provides simplicity is the three-position seed gate. Traditionally, producers have had to manually insert rubber plugs to change row spacings. With the ease of a sliding gate, the feeder cup can quickly and conveniently be adjusted to meter different types of seed, or closed completely for skip-rows. While small grains are typically seeded on narrow spacing (7 .5" or 10"), other crops, such as soybeans or other legumes, are often grown on wider rows (15", 20", or 30"). Closing the seed gate door on every other row quickly converts the drill from 7 .5" to 15" row spacing. If using the drill to plant cover crops, there may be scenarios where wider rows (15") or a skip-row every 30" (three planted rows on 7 .5" spacing or two planted rows on 10" spacing) is desired to allow for easier planting of the subsequent cash crop.

With a centralized, five-position seed gate handle, adjusting the feeder cup for different seed sizes or cleaning out the feeder cup has never been easier. Each section of the BD7600 has a Thandle for adjusting the chevron seed gate on each feeder cup. Five settings are available to handle a wide variety of seed sizes, as well as a cleanout position. This centralized T-handle provides increased functionality and saves farmers valuable time by no longer having to adjust the seed gate on each individual feeder cup. This is particularly useful when the drill needs a thorough cleaning, such as when changing between seed types or varieties.

Simplifying calibration was a vital part of the BD7600 design process. Proper calibration prior to seeding is critical to ensuring that the desired seeding rate is achieved. Seed size, seed treatment, and the environment are all factors that can affect how seeds are metered. Though calibration does take time, without it, crop stands and yields can be compromised by overlooking its importance. Compared to competitive calibration procedures, Great Plains has designed the BD7600 to be simple and efficient to calibrate, minimizing the time spent away from seeding. To further simplify calibration, Great Plains developed a QR code decal, located on the toolbox on the tongue of the drill, that links to a video showcasing the calibration process.

At the bottom of the feeder cup, the removable funnel easily detaches for inspection and calibration. Other drills require the seed hoses to be removed from either the meter or opener body, which requires a pair of pliers and a significant amount of time. A collapsible calibration bag is provided with the BD7600 to catch the seed for the calibration test and attaches securely beneath the feeder cups. In addition to the seed bag, a scale is provided to ensure an accurate weight is recorded with each calibration. These calibration tools are stored in a toolbox located on the tongue of the BD7600. This ensures these tools will be available whenever a calibration is needed - greatly reducing the time required to perform a money-saving calibration.

We know the drill. You told us what features you needed in a grain drill, and we listened. If you're looking for a drill with versatility, innovation, and simplicity, the BD7600 will provide legendary results.

Learn more about the BD7600 drill or by contacting your local Kubota / Great Plains dealer.